Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

|

Product : Ultrasonic Flaw Detector

Model : DUT-1800A

Country of Origin : CHINA

Brand : DTEC

Quality Certified : ISO,CE

Delivery Time : 5 days

Packing Weight : 6KG

Dimension : 45x38x13cm(LxWxH)

Package Type : Maker's Standard Export Carton Box

Courier : DHL/TNT/FedEx/UPS/EMS,Shipping Agent

Payment Term : TT100%/Private Bank Account/L/C/Paypal/Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

and function of Φ Value calculation.

Using Scopes:

The instrument can be quickly, nondestructively and accurately used in locating and sizing hidden cracks, voids, disbands, and similar discontinuities in welds, forgings, billets, axles, shafts, tanks and pressure vessels, turbines, and structural components.

The Main Difference among the four models:

|

Model |

DUT-1000 |

DUT-1000A |

DUT-1800 |

DUT-1800A |

|

True Color TFT LCD |

√ |

√ |

√ |

√ |

|

DAC Curve |

√ |

√ |

√ |

√ |

|

AVG Curve |

χ |

√ |

χ |

√ |

|

Φ Value Calculation |

χ |

√ |

χ |

√ |

|

Distance Compensation |

χ |

√ |

χ |

√ |

|

Changeable Squared Ultrasonic Pulse |

χ |

χ |

√ |

√ |

|

Wide/Narrow Band Filters |

χ |

χ |

√ |

√ |

|

Four Impedance Matching |

χ |

χ |

√ |

√ |

|

Data Logger |

√ |

√ |

√ |

√ |

|

UtView Software |

√ |

√ |

√ |

√ |

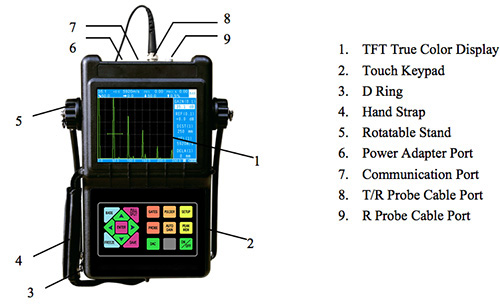

Major Structure of the Instrument

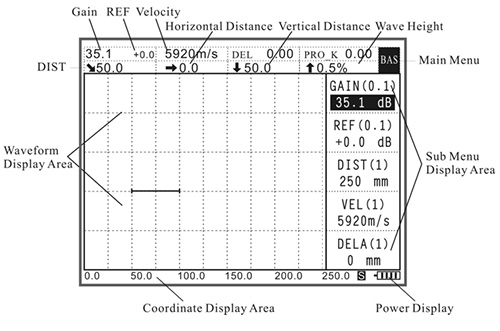

Power on the instrument (the probe is not connected), and the screen is shown as following:

A pack of exclusive rechargeable built-in batteries or 6 pcs.common LR14 batteries can be used in DUF-1800A, as shown:

Main Menu:

|

Main Menu

|

Submenu Functions

|

Guide

|

|

Basic

|

Gain, Compensation, Sound Velocity, Sound Path, Displacement, Scale, Reject, Wave Height Readings |

Basic Parameters in Detection

|

|

Setting

|

Waveform Filling, Color Scheme, Language, Unit, Alarm, Automatic Wave Height, Date, Time, Parameter Resetting, Lighting |

Basic Functions of the Instrument

|

|

Gate

|

Gate A Start, Gate A Width, Gate A Height, Gate A Mode, Display Mode, Gate B Start, Gate B Width, Gate B Height, Gate B Mode, Measurement Point |

Relevant Options Setting Gate

|

|

Probe

|

Dual Probes, Probe Zero, Probe K Value, Front Edge Length, Work Piece Thickness |

Relevant Options Setting Probe

|

|

Curve

|

DAC Echo, Gate A Start Position, RL, SL, EL |

Setting of Making DAC Curve

|

|

Storage

|

Memory Number, Call Out, Storage, Deletion, Communication |

Setting of Data Storage

|

Functional Keys:

|

Automatic Gain |

Increase or decrease the highest wave inside the gate to 80% of the screen |

|

Freezing

|

Waveform freezing |

|

Wave Peak Memory |

Automatically store the highest wave |

|

Full Screen |

Full screen display |

|

On/Off

|

Switch on and off |

|

Menu Control Keys Up, Down, Left, Right, Ok |

Up/down keys are used to switch among options, left/right keys are used to adjust values. |

►Pan-seal Design of IP67 Standard, Real Waterproof, Waterproof, and Dustproof;

►Two battery schemes(unique in China):when there is no AC supply, if the battery pact exhausts, you can use 6 ordinary LR14 batteries;

►31 copper screw nuts are inlaid in the hard plastic casing;

►Innovative rotating positioning stand,which is convenient to place instrument anywhere;

►Hand strap installed enable to hold the machine with any hand;

►Selectable for BNC or LEMO probe port;

►D-shaped ring on the instrument convenient for you to install a chest-strap;

►Full screen function, the echo display area can cover the entire screen, satisfying you the feeling of the maximum window;

►Solid waveform display, which strengthens the visual contrast of waveforms ,make it hard to miss detection when fast scan is carried out;

►Bulk storage, up to 1000 data sets can be stored, including waveforms, curves, and parameters (containing the traditional 1000 channels);

►Echo-echo thickness measurement, zero calibration is avoided, and the net thickness of the base material can be directly measured through the coating;

►Easy to use, the user can master the operation method fast;

►The squared ultrasonic pulse generator with changeable width and scope is initiative domestically. It replaces the traditional method of matching probe by changing damping with adjusting the pulse energy and pulse width. Thus, the probe can be exactly fit for the testing and the resolution and penetrating power of the approaching surface can be enhanced significantly. It is specially fit for the testing of large scale of forge piece, casting piece and non-metal with the requirement of higher penetrating power and lower electric noise;

•The voltage of the pulse generator can be changed between 50V to 400V continuously, so that no matter thin plate or hard-penetrated work-piece can be matched with the most fitful probe.

•The width of the pulse can be change d between 25ns to 1000ns continuously, so that the best sensitivity can be realized with the help of different probes with different frequency.

►Damping can be changed among 4 levels: 33/50/100/500Ω, so that the best performance of the probe can be attained and the different requirements of the sensitivity and resolution can be realized;

►The wave signal filter can be changed between 2 levels: 1-4MHz/0.5-15MHz. Each individual advantage of narrowband and broadband filter can be achieved;

►The repeating frequency can be changed freely to avoid unreal signal.

Basic Functions:

►Wave peak memory: real time envelopes show the highest wave of the flaws and record the maximum value of the flaws, it is helpful to position the flaws precisely and scan the work piece quickly. With the help of envelope waveform, the quality of the flaws can be determined;

►Automatic gain: automatically adjust the gain to the preset amplitude height;

►Alarming function: afferent echo/echo loss alarming;

►Real-time clock: automatically record and store the date and time of waveforms;

►Display freezing: catch waveforms and sound path data at any moment, and the gate can be moved after freezing to measure the echo parameters;

►Flaw positioning: real-time display sound path S, horizontal X, depth Y, and wave height H;

►Digital Reject: 0-80%, increase by 1%, unaffecting the linearity and gain;

►Wave height reading: three display modes, namely relative wave height, dB difference relative to the gate, and dB difference relative to DAC curve;

►Data communication: communicate with the computer through RS232 port to transmit waveforms and data so as to manage the result of detection on the computer, and generate the flaw detection reports, as well as print out reports;

►Two independent measurement gates:monitoring the echo amplitude and the sound path distance;

►When using transverse wave to detect flaws, the depths of the second and third waves are automatically calculated according to the slab thickness;

►Perfect DAC/AVG curve functions:the curves change along with the changes of the gain, sound path, and displacement;

►5.7’’True color TFT LCD:whose brightness is adjustable, with many color schemes to choose freely;

►DAC Curvilinear Distance Compensation: the device is designed for distance compensation. When the resolving power in the near field is not influenced, only the remote signal will be compensated for its sensitivity so as to improve the testing range of the device significantly;

►Φ Value calculation: the device can calculate the equivalent of the flaw according to the flaw wave height automatically.

|

Testing Range

|

0-177 inch or 0-4500 mm

|

|

Working Frequency

|

0.5-15 MHz

|

|

Material Sound Velocity |

0.039-0.394 inch/µs or 1000-9999 m/s

|

|

Resolution

|

≥32dB (5P14) |

|

Pulse Displacement

|

0-7.87 inch

|

|

Probe Zero

|

0-99.99 µs

|

|

Damp

|

33/50/100/500Ω

|

|

Displaying

|

True Color TFT LCD Screen (5.7’’) |

|

Operating Mode

|

Pulse Echo /Dual Crystal |

|

DAC/AVG Curve

|

Perfect DAC and AVG Curve Function, Function of DAC Curvilinear Distance Compensation |

|

Gain Adjustment

|

(0-110)dB,0.1dB,1.0dB,2.0dB,6.0dB

(Full Automatic Adjustment of Steps)

|

|

Reject Scope |

0-80% Adjustable

|

|

Vertical Linearity Error |

≤3%

|

|

Horizontal Linearity Error |

≤0.3%

|

|

Dynamic Range |

≥30dB

|

|

Sensitivity Allowance |

≥55dB (0.787’’ Deep Φ2 Flat-bottom Hole) |

|

Data Storage |

1000 Data Sets, Including Flaw Detection Status Parameters, Echoes and DAC Curves |

|

Average Electric Noise and Level |

≤10%

|

|

Battery Types |

6 Pcs. Ordinary LR14 Batteries or High Power Lithium Battery |

|

Power Supply

|

220V AC, 12V DC

|

|

Working Hours

|

> 8 Hours

|

|

Enclosure

|

Pan-seal Design of IP67 Standard, Real Waterproof, Waterproof, and Dustproof. |

|

Working Temperature |

14℉ to 122℉ |

|

Dimension

|

45x38x13cm

|

|

Packing Weight

|

6KG

|

|

Items

|

Qty.

|

Items

|

Qty.

|

|

Main Unit

|

1

|

Normal/Angle Probe

|

1 each

|

|

Recharger

|

1

|

Strap

|

1

|

|

Probe Cable

|

2

|

Instrument Case

|

1

|

|

Data Processing Software

|

1

|

Warranty Card, User’s Manual Quality Certificate Packing List

|

1 each

|

|

Communication Cable

|

1

|

Lithium Battery

|

1

|