Contact Us

Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

|

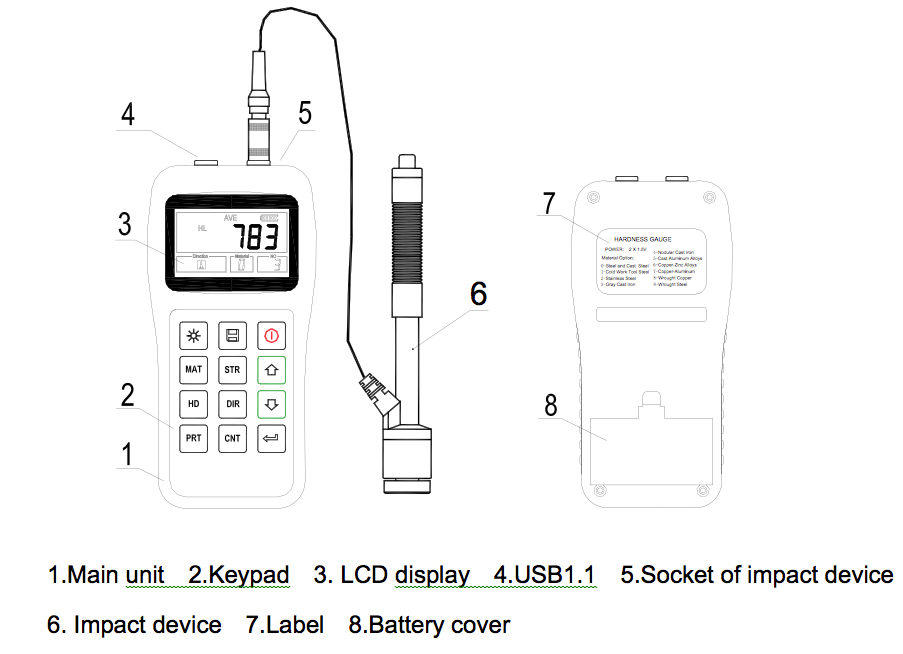

Product : Portable Hardness Tester

Model : MH180

Country of Origin : CHINA

Brand : DTEC

Quality Certified : CE,ISO,Ghost

Delivery Time : 3 days

Packing Weight : 6KG

Dimension : 37x30x12cm(LxWxH)

Package Type : Maker's Standard Export Wooden Case

Courier : DHL/TNT/FedEx/UPS/EMS/Shipping Agent

Payment Term : TT100%/Private Bank Account/L/C/Paypal/Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

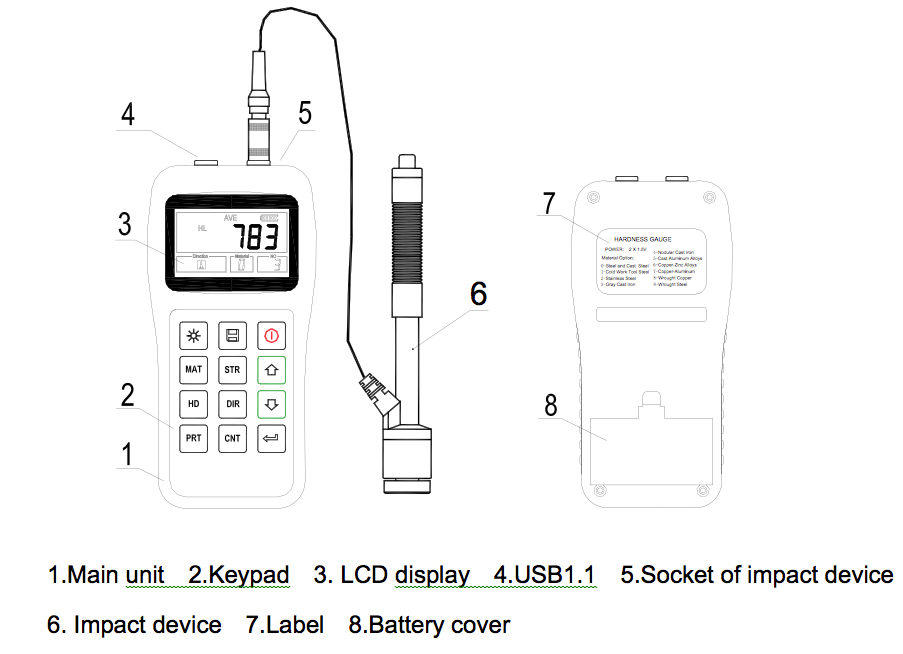

MH180 Portable Hardness Tester is an economical and foundational model among all, equips with USB 1.1 data port, it can match with optional data pro software and connect to PC to do further analysis. Similarly, It has segment large LCD digital screen, which is easy operated. Customers who do the test without printing on-site, at the same time, considering about the purchase budget, this is the right choice.

Main Application:

Die cavity of molds

Bearings and other parts

Failure analysis of pressure vessel, steam generator and other equipment

Heavy work piece

The installed machinery and permanently assembled parts

Testing surface of a small hollow space

Material identification in the warehouse of metallic materials

Rapid testing in large range and multi-measuring areas for large-scale work piece.

Main Application:

Die cavity of molds

Bearings and other parts

Failure analysis of pressure vessel, steam generator and other equipment

Heavy work piece

The installed machinery and permanently assembled parts

Testing surface of a small hollow space

Material identification in the warehouse of metallic materials

Rapid testing in large range and multi-measuring areas for large-scale work piece.

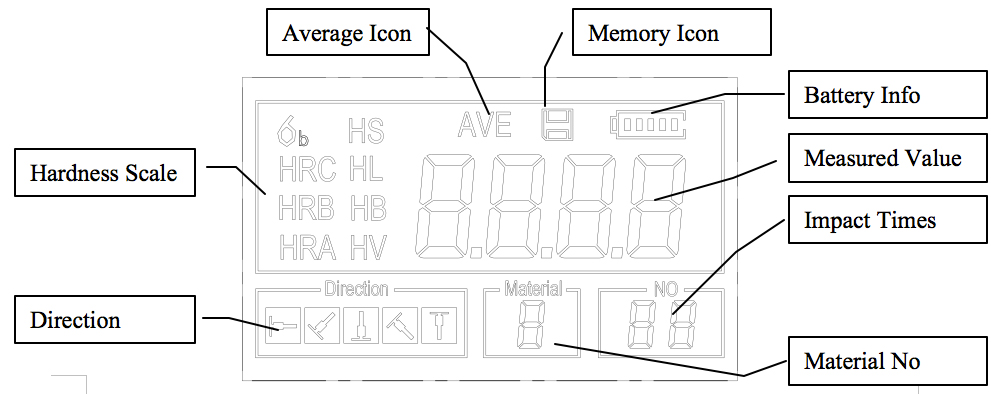

►Segment LCD Large Digital screen, displaying figures, with EL background light;

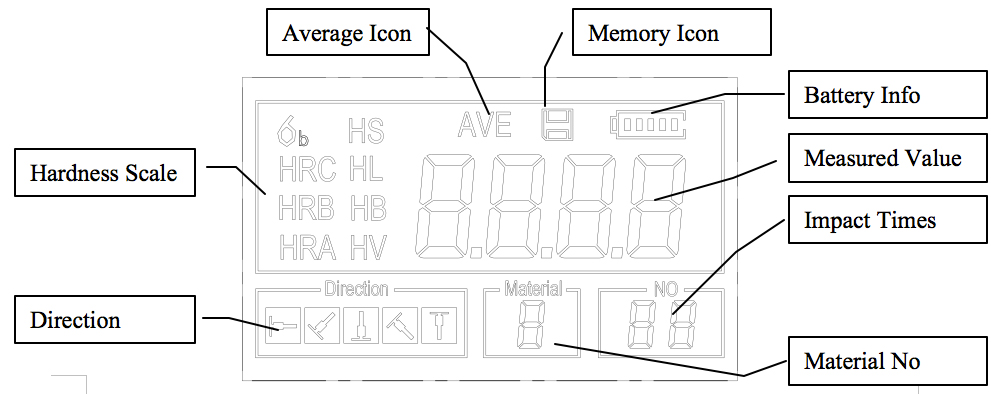

►6 Exchangeable hardness scales: HRB, HRC, HV, HB, HS, HL, 3 types of strength values, Suitable to measure the hardness of all metallic materials;

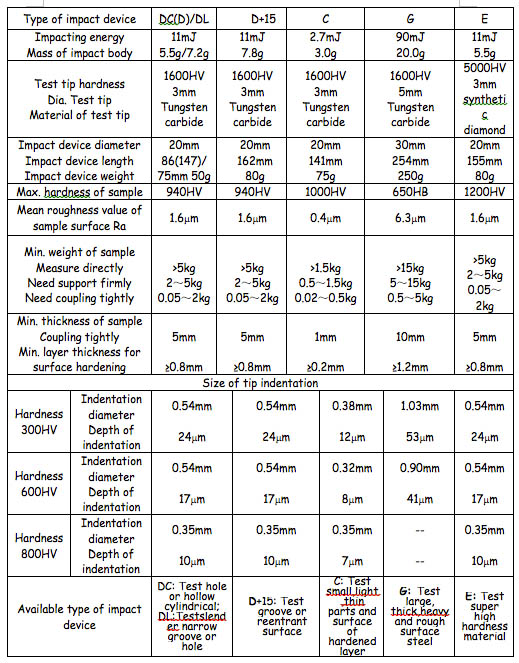

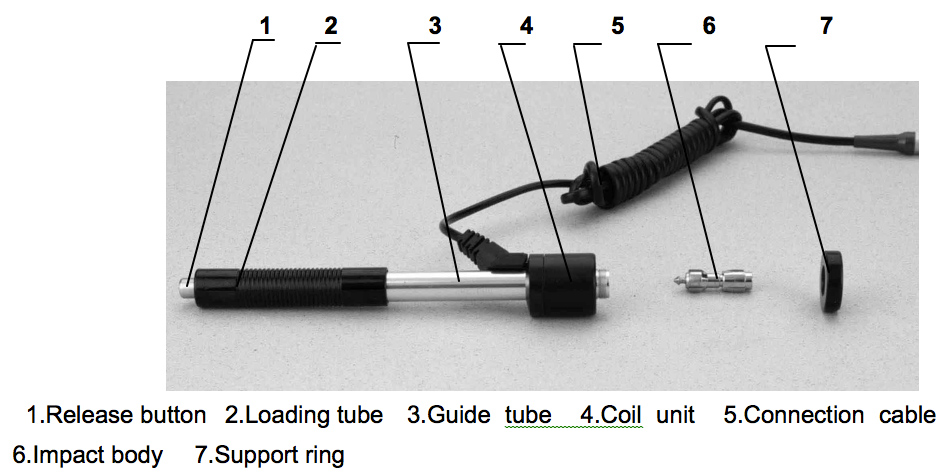

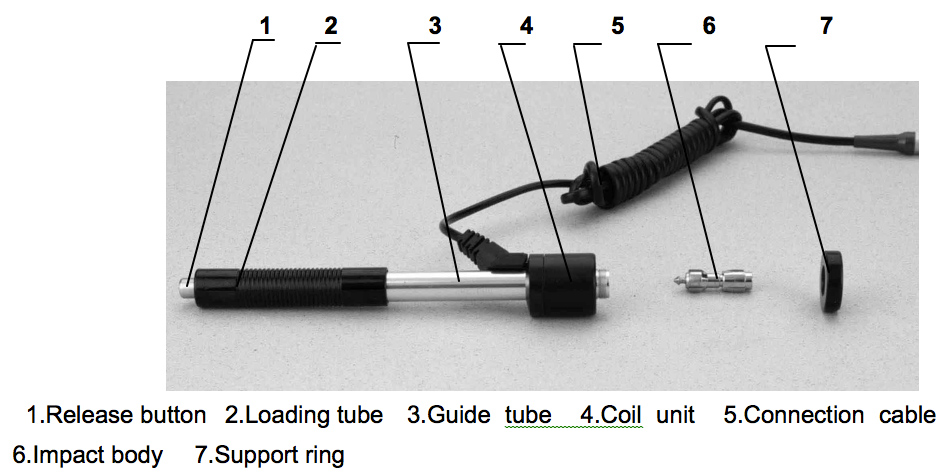

►7 impact devices available for special usage, automatically identify the type of impact devices;

►100 groups storage capacity, including single measured value, average value, testing data, impact direction, impact times, material and hardness scale etc;

►Compact plastic case,suitable for use under poor working conditions. Test at any angle, even upside down;

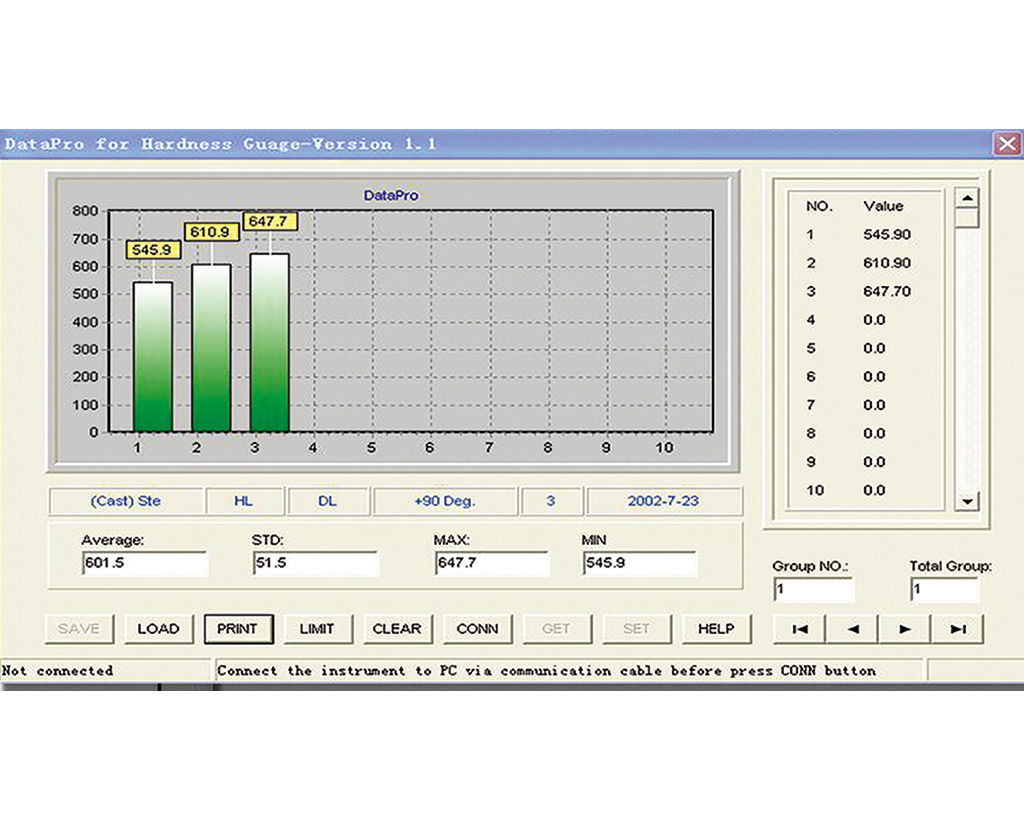

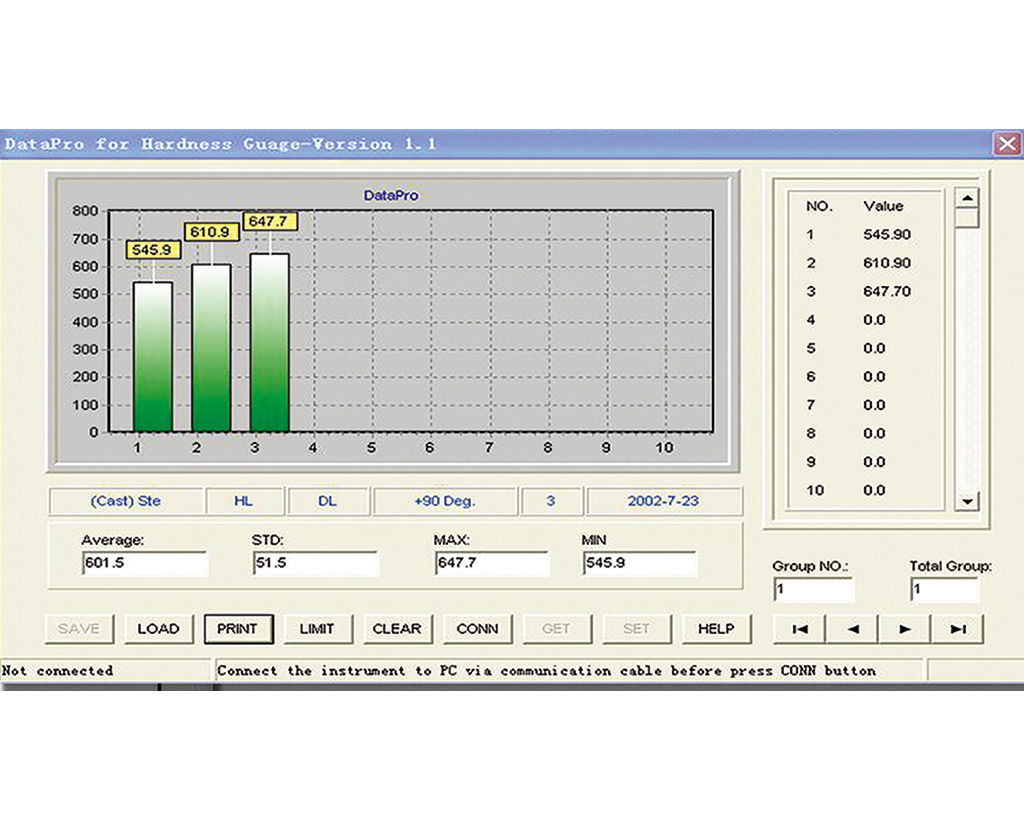

►Equips with USB1.1 port, suitable to match with optional data proceeding software, enable to connect to PC and make further data analysis;

►Humanized user calibration function;

►Two AA Size battery, continuous working time of nealy 100 hours after full charge(EL off);

►Auto power off set to save energy;

►Excellent after-sale service system for high quality products---two years’ guarantee and all life maintenance. Easy to buy and convenient to use.

►6 Exchangeable hardness scales: HRB, HRC, HV, HB, HS, HL, 3 types of strength values, Suitable to measure the hardness of all metallic materials;

►7 impact devices available for special usage, automatically identify the type of impact devices;

►100 groups storage capacity, including single measured value, average value, testing data, impact direction, impact times, material and hardness scale etc;

►Compact plastic case,suitable for use under poor working conditions. Test at any angle, even upside down;

►Equips with USB1.1 port, suitable to match with optional data proceeding software, enable to connect to PC and make further data analysis;

►Humanized user calibration function;

►Two AA Size battery, continuous working time of nealy 100 hours after full charge(EL off);

►Auto power off set to save energy;

►Excellent after-sale service system for high quality products---two years’ guarantee and all life maintenance. Easy to buy and convenient to use.

|

Testing Range

|

In Steel:(170-960)HLD,(17-68.5)HRC,(19-651)HB,(80-976)HV,(30-100)HS,(59-85)HRA,(13-100)HRB |

|

Testing Direction

|

360°

|

|

Hardness Scale

|

HL,HB,HRB,HRC,HRA,HV,HS.

|

|

Display Mode

|

Segment LCD

|

|

Data Memory

|

100 groups max.(relative to impact times 32~1) |

|

Printing Paper

|

Width:(57.5±0.5)mm;Dia.:30mm

|

|

Battery Pack

|

Two AA Size

|

|

Battery Charger

|

3V/500mA

|

|

Continuous Working Hours

|

about 100 hours(With backlight off, no printing) |

|

Communication Interface

|

USB1.1

|

|

Dimension

|

37x30x12cm(LxWxH)

|

|

Packing Weight

|

6KG

|

Error and Repeatability of Displayed Value:

|

No.

|

Type of impact device

|

Hardness value of Leeb standard hardness block |

Error of displayed value |

Repeatability

|

|

1

|

D

|

760±30HLD

530±40HLD

|

±6 HLD

±10 HLD

|

6 HLD

10 HLD

|

|

2

|

DC

|

760±30HLDC

530±40HLDC

|

±6 HLDC

±10 HLDC

|

6 HLD

10 HLD

|

|

3

|

DL

|

878±30HLDL

736±40HLDL

|

±12 HLDL

|

12 HLDL

|

|

4

|

D+15

|

766±30HLD+15

544±40HLD+15

|

±12 HLD+15

|

12 HLD+15

|

|

5

|

G

|

590±40HLG

500±40HLG

|

±12 HLG |

12 HLG |

|

6

|

E

|

725±30HLE

508±40HLE

|

±12 HLE |

12 HLE |

|

7

|

C

|

822±30HLC

590±40HLC

|

±12 HLC

|

12 HLC

|

Testing Range in Different Materials with Different Impact Devices:

|

Material

|

Method

|

Impact device

|

|||||

|

D/DC

|

D+15

|

C

|

G

|

E

|

DL

|

||

|

Steel and cast steel

|

HRC

|

20~68.5

|

19.3~67.9

|

20.0~69.5

|

|

22.4~70.7

|

20.6~68.2

|

|

HRB

|

38.4~99.6

|

|

|

47.7~99.9

|

|

37.0~99.9

|

|

|

HRA

|

59.1~85.8

|

|

|

|

61.7~88.0

|

|

|

|

HB

|

127~651

|

80~638

|

80~683

|

90~646

|

83~663

|

81~646

|

|

|

HV

|

83~976

|

80~937

|

80~996

|

|

84~1042

|

80~950

|

|

|

HS

|

32.2~99.5

|

33.3~99.3

|

31.8~102.1

|

|

35.8~102.6

|

30.6~96.8

|

|

|

Cold work

tool steel

|

HRC

|

20.4~67.1

|

19.8~68.2

|

20.7~68.2

|

|

22.6~70.2

|

|

|

HV

|

80~898

|

80~935

|

100~941

|

|

82~1009

|

|

|

|

Stainless steel

|

HRB

|

46.5~101.7

|

|

|

|

|

|

|

HB

|

85~655

|

|

|

|

|

|

|

|

HV

|

85~802

|

|

|

|

|

|

|

|

Grey cast iron

|

HRC

|

|

|

|

|

|

|

|

HB

|

93~334

|

|

|

92~326

|

|

|

|

|

HV

|

|

|

|

|

|

|

|

|

Nodular cast iron

|

HRC

|

|

|

|

|

|

|

|

HB

|

131~387

|

|

|

127~364

|

|

|

|

|

HV

|

|

|

|

|

|

|

|

|

Cast aluminum alloys

|

HB

|

19~164

|

|

23~210

|

32~168

|

|

|

|

HRB

|

23.8~84.6

|

|

22.7~85.0

|

23.8~85.5

|

|

|

|

|

BRASS(copper-zinc alloys)

|

HB

|

40~173

|

|

|

|

|

|

|

HRB

|

13.5~95.3

|

|

|

|

|

|

|

|

BRONZE(copper-aluminum/tin alloys)

|

HB

|

60~290

|

|

|

|

|

|

|

Wrought copper alloys

|

HB

|

45~315

|

|

|

|

|

|

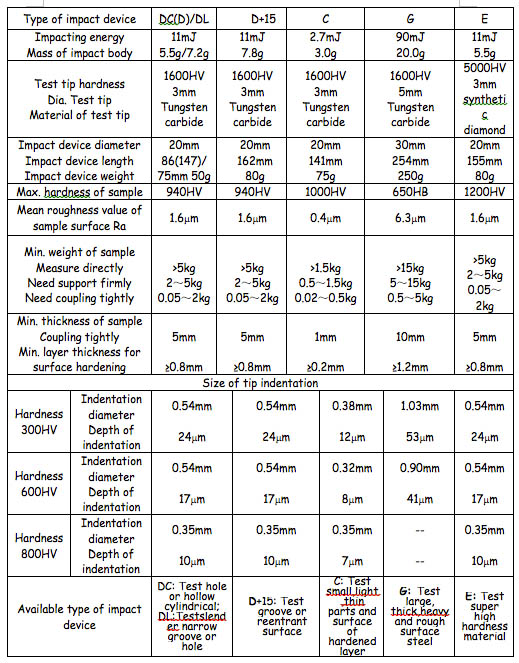

Testing Parameter of Impact Devices:

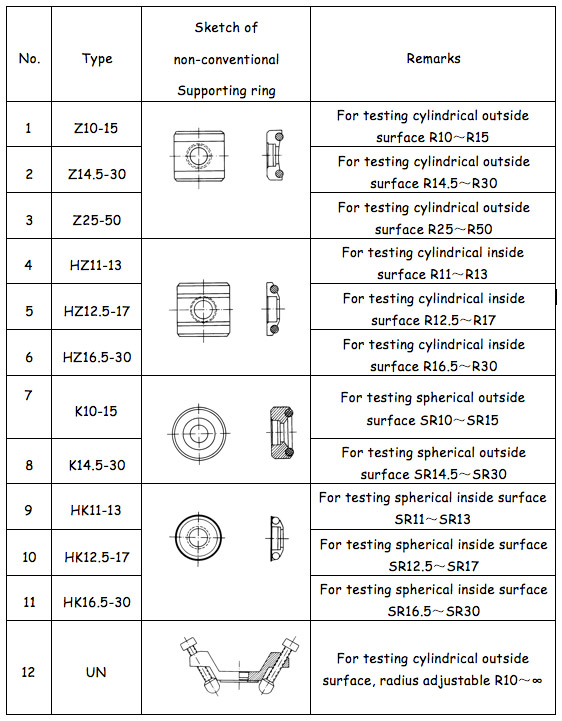

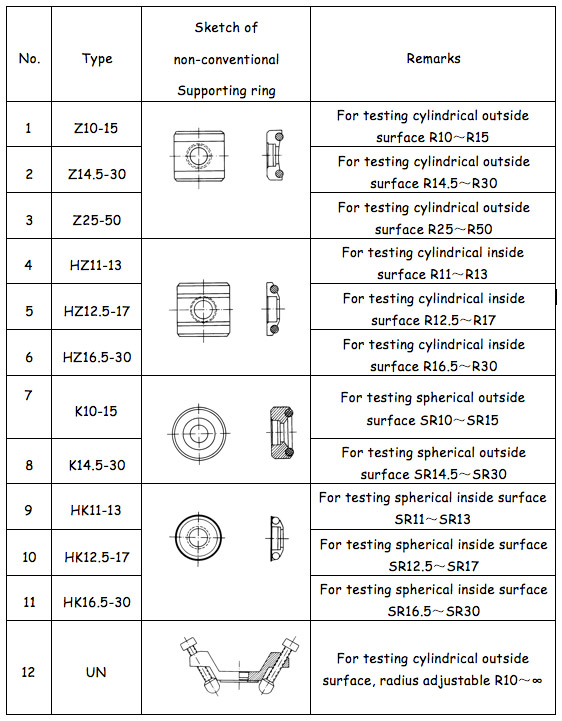

Specification of Supporting Rings:

Specification of Supporting Rings:

Standard Packing Accessories:

|

No.

|

Items

|

Qty.

|

Remarks

|

|

1

|

Main unit |

1

|

|

|

2

|

D type impact device |

1

|

With cable |

|

3

|

Standard Hardness Block |

1

|

|

|

4

|

Cleaning brush (I) |

1

|

|

|

5

|

Small support ring |

1

|

|

|

6

|

Battery Charger |

1

|

9V 500mA |

|

7

|

Manual Book, Warranty Card, Quality Certificate | ||

|

8

|

Pakage Case | 1 |

Optional Accessories:

Data Pro Software

Impact Devices(D/C/DC/DL/D+15/E/G)

Cable for Impact Device (D/C/DC/DL/D+15/E/G)

Impact Body (D/C/DC/DL/D+15/E/G)

Supporting Rings(12 pcs. each set)

Data Pro Software

Impact Devices(D/C/DC/DL/D+15/E/G)

Cable for Impact Device (D/C/DC/DL/D+15/E/G)

Impact Body (D/C/DC/DL/D+15/E/G)

Supporting Rings(12 pcs. each set)