Contact Us

Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

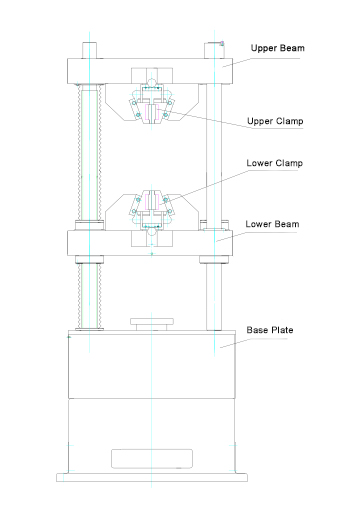

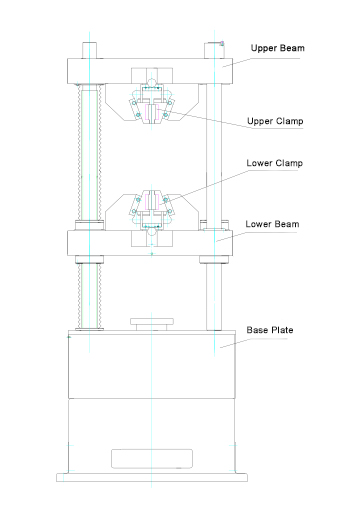

Products > Material Testing Equipment > Universal Testing Machine > Digital Hydraulic Universal Testing Machine

|

Product : Digital Hydraulic Universal Testing Machine

Model : DE-300D/600D/1000D

Country of Origin : CHINA

Brand : DTEC

Quality Certified : GB/T2611,ISO,ASTM,DIN

Delivery Time : 10 working days

Packing Weight : 1900-3500KG

Dimension : 950x800x2300cm(LxWxH) Approximately

Package Type : Maker's Standard Export Wooden Case

Courier : DHL/TNT/FedEx/UPS/EMS/Shipping Agent

Payment Term : TT100%/Private Bank Account/L/C/Paypal/Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

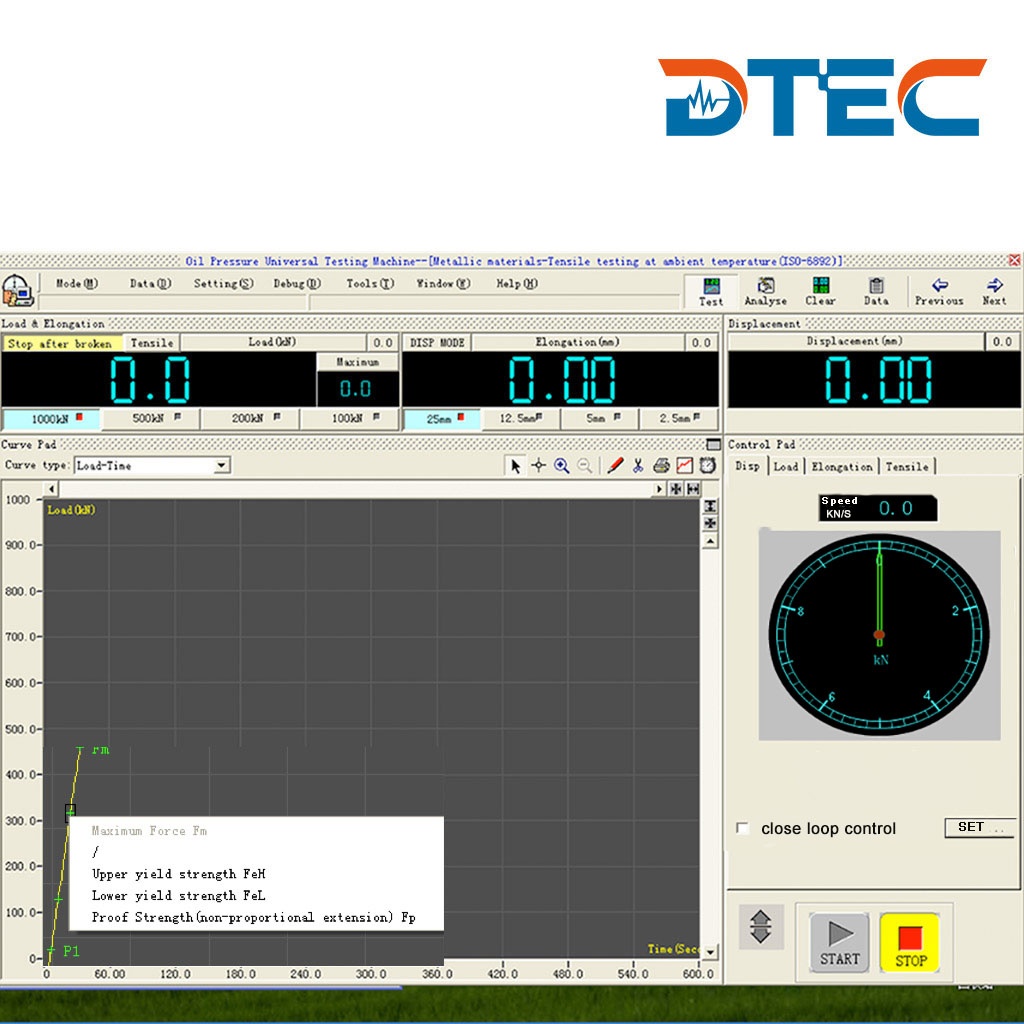

DE Series Digital Hydraulic Universal Testing Machine is mainly applicable for on-site tests, such as on-line inspection in the filed of ferrous metallurgy, transportation construction, machinery production, construction engineering and electric power fitting etc. It can display testing forces and displacement data, analyze indexes on tensile strength, maximum force and elongation,the equipment can be optional with printer and print out testing data.

Main Engine:

The main engine of Hydraulic Universal Testing Machine is the one with underneath oil cylinder, which is clearance seal type (the bottom clearance is sealed by oil slick, which keep it from deformation,wearing and leaking after long time’s work).

Main Engine:

The main engine of Hydraulic Universal Testing Machine is the one with underneath oil cylinder, which is clearance seal type (the bottom clearance is sealed by oil slick, which keep it from deformation,wearing and leaking after long time’s work).

►Without Measuring Force Level during the whole test, with functions of force protection and break point setting;

Function of displaying testing force, testing force peak and testing force rate;

►Functions of zeroing testing force, peak holding, parameter setting, calibration and fine turning;

►LED high-brightness screen, operation experience is not required, simple operation;

►Functions of storing and factory settings;

►Optional Micro printer, freely printing the test results;

►Suitable to externally connect to photoelectric encoder, achieving the function of high-precision measurement and display of piston displacement.

Function of displaying testing force, testing force peak and testing force rate;

►Functions of zeroing testing force, peak holding, parameter setting, calibration and fine turning;

►LED high-brightness screen, operation experience is not required, simple operation;

►Functions of storing and factory settings;

►Optional Micro printer, freely printing the test results;

►Suitable to externally connect to photoelectric encoder, achieving the function of high-precision measurement and display of piston displacement.

|

Series Models

|

DE

|

|||

|

300D

|

600D

|

1000D

|

||

|

Max. Testing Force (KN)

|

300

|

600

|

1000

|

|

|

Measuring Range

|

0.4%-100% of the maximum testing force

|

|||

|

Relative Error on Indicated Values of Testing Force |

Better Than ±1% of the Indicated Value

|

|||

|

Deformation Precision

|

±01%(orv±0.5%)

|

|||

|

Tensile Space

|

550mm

|

600mm

|

600mm

|

|

|

Compression Space

|

≥500mm

|

|||

|

Clamping Dia. Of Round Specimens (mm)

|

Φ6-Φ26

|

Φ13-Φ40

|

Φ13-Φ60

|

|

|

Clamping Thickness Of Flat Specimens (mm)

|

0-15mm

|

0-30mm

|

0-40mm

|

|

|

Diameter of Shearing Specimens

|

10mm(Optional)

|

|||

|

Diameter of Upper and Lower Pressing Plate |

Φ120mm (Optional 204mmx204mm) |

|||

|

Maximum Distance Between Bending Fulcrums |

Optional

|

|||

|

Power of Oil Pump Motor

|

1.1KW

|

|||

|

Power of Beam Up-down Movable Motor |

0.75KW

|

|||

|

Weight (Approximate KG)

|

1900

|

2600

|

3500

|

|

|

Safety Protective Device

|

Software Protection and Mechanical Limit Protection |

|||

|

Clamp Type

|

Manual Clamping/Automatic Clamping |

|||

Standard Packing:

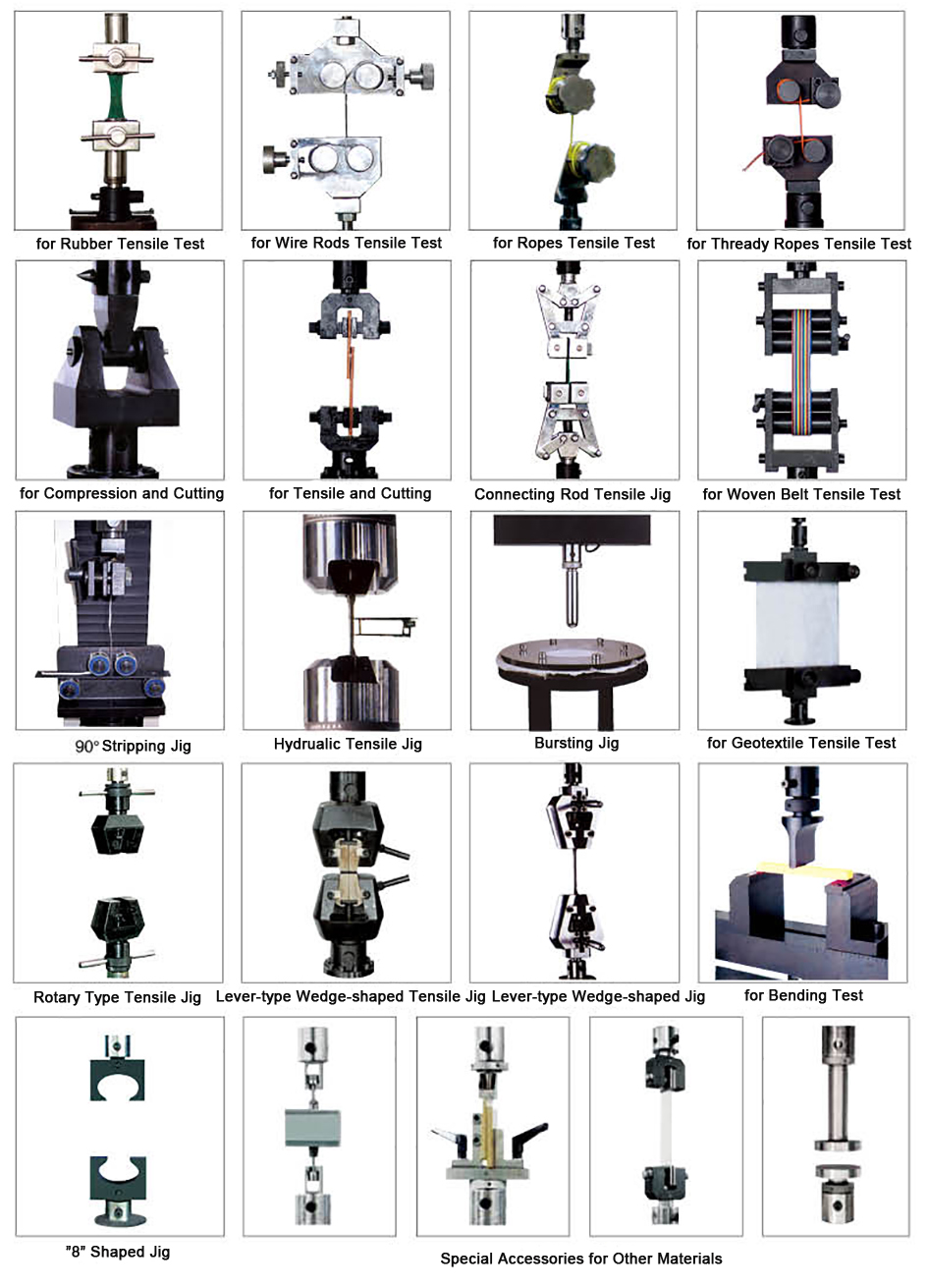

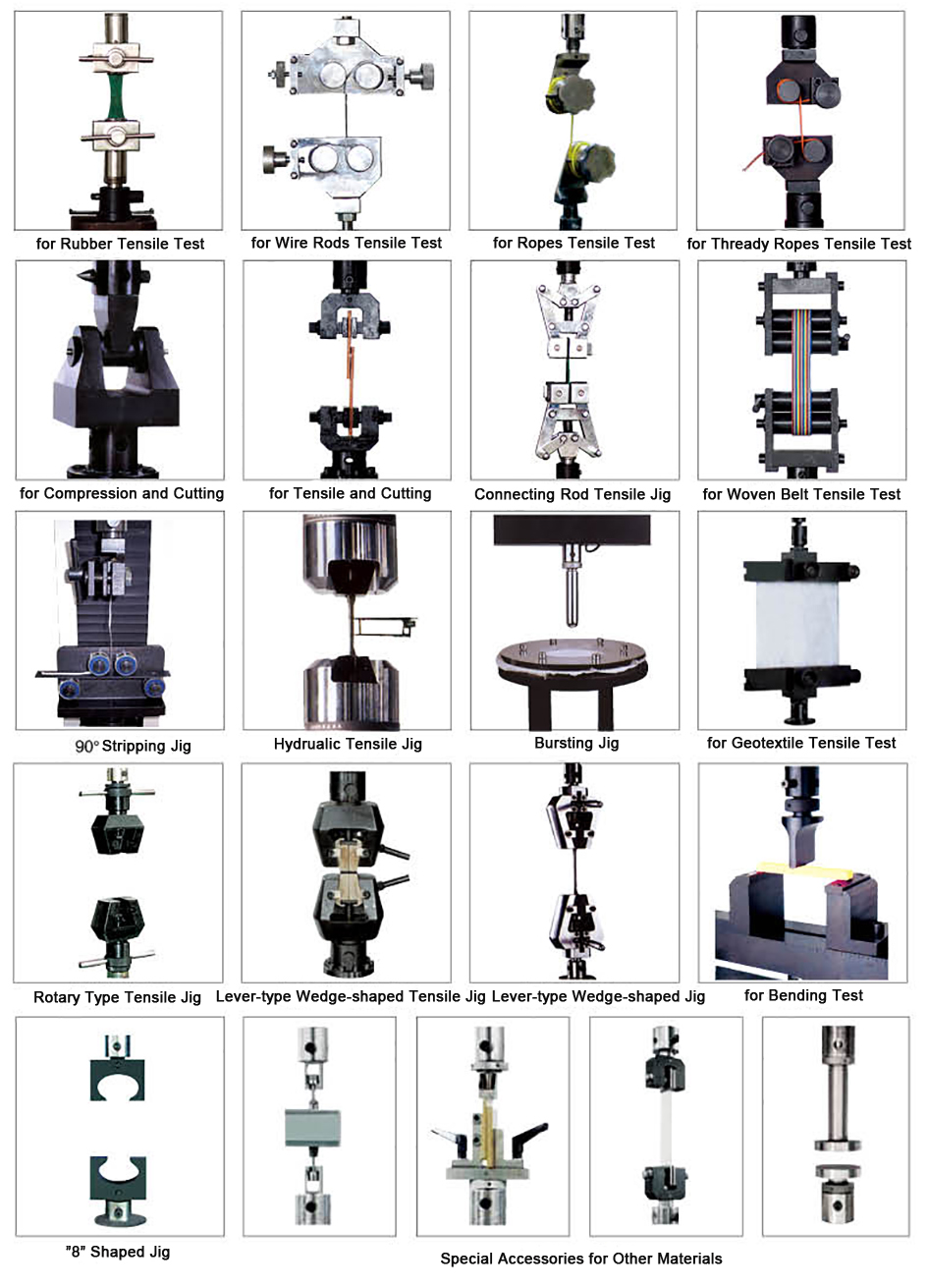

Optional Accessories:

|

No.

|

Items

|

Qty.

|

|

1

|

Main Unit (Clearance Seal Oil Cylinder)

|

1

|

|

2

|

Desktop Specialized Oil Source for Displaying Type |

1 Set

|

|

3

|

Manual Valve for Oil-in and Oil-out |

Each 1

|

|

4

|

Dual Channel Program Control AMP

|

1 Set

|

|

5

|

High-Precision Oil Pressure Transducer |

1

|

|

6

|

High-precision photoelectric encoder |

1

|

|

7

|

Flat Jig (0-20mm)

|

1

|

|

8

|

Round Jig (26-40mm,40-60mm)

|

Each 1

|

|

9

|

Bending Accessories

|

1 Set

|

|

10

|

Extensometer (50/25)

|

1

|

|

11

|

Data Pro Software System (Including general software for UTM displayer and its connecting system) |

1 Set

|

|

12

|

Manual Book, Quality Certificate

|

Each 1

|

Optional Accessories: