Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

|

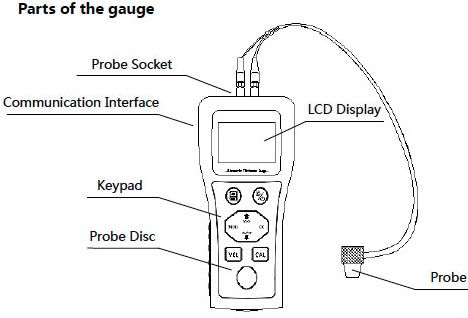

Product : Ultrasonic Thickness Gauge

Model : DT300

Country of Origin : CHINA

Brand : DTEC

Quality Certified : ISO,CE

Delivery Time : 3 days

Packing Weight : 2KG

Dimension : 36x25x14CM(LxWxH)

Package Type : Maker's Standard Export Carton Box

Courier : DHL/TNT/FedEx/UPS/EMS,Shipping Agent

Payment Term : TT100%/Private Bank Account/L/C/Paypal/Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

It is suitable for a large variety of metallic such as steel, cast iron, aluminum, copper, and non-metallic materials such as plastic, ceramics, glass, etc., which is widely used in the fields of metallurgy, railway, shipping, aviation, oil etc.

►Measuring the thickness of various material with resolution as high as 0.01mm or 0.001 inch;

►Can measure various materials not only metallic steel, cast iron,alumnum,copper, but also non-metallic, plastic ceramic,glass,glass fiber and so on;

►Five types of selectable probes with 3 adjustable gain levels to meet different measuring conditions;

►Mini-USB interface used for communication with PC;

►Standard host software is upgradable, supporting online measurement;

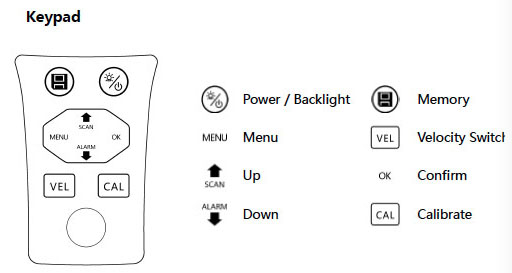

►Two Calibration modes-Zero Calibration and Two-Point Calibration can be used to automatically correct system error;

►Support many measurement modes, such as single point mode, scanning mode, differrential mode and alarm mode;

►Sound velocity can be measured by a known thickness sample workpiece;

►500 groups of storage capacity, enable to completely store the thickness data and sound velocity information;

►Stability indicator for measuring status monitoring;

►Battery indicator for battery quantity monitoring.

|

Model

|

DT300 (G5M-P10)

|

||||

|

Probe Type

|

G5M-P10

|

G5M-P08

|

G2M-P12

|

G7M-P06

|

H3M-P12

|

|

Testing Range (in Steel)

|

0.8-300mm

|

0.8-300mm

|

2.0-400mm

|

0.75-40mm

|

3.0-100mm

|

|

Probe Diameter

|

10mm

|

8mm

|

12mm

|

6mm

|

12mm

|

|

Frequency

|

5MHz

|

5MHz

|

2MHz

|

7.5MHz

|

3MHz

|

|

Contact Temperature

|

-10-60℃

|

-10-60℃

|

-10-60℃

|

-10-60℃

|

-10-310℃

|

|

Min. Testing Diameter

|

Φ25x3 mm

|

Φ20x1.2 mm

|

Φ30x4 mm

|

Φ15x1.2mm

|

Φ25x3 mm

|

|

Accuracy

|

Thickness<10mm: ±0.05mm

|

||||

|

Thickness≥10mm: ±(0.5%*H) mm

|

|||||

|

Testing Alternation

|

4 times/sec

|

||||

|

Resolution

|

0.01mm/0.001inch

|

||||

|

Sound Velocity Range

|

1-9999 m/s

|

||||

|

Sound Velocity Measuring

|

Of known thickness can be measured Sound Velocity

|

||||

|

Gain Adjustable

|

3 Level Gain Adjustable

|

||||

|

Calibration Mode

|

Zero-point, Two-point

|

||||

|

Displaying Mode

|

MENU Operate, English FSTN LCD Display with Backlight |

||||

|

Measuring Mode

|

One-point mode, Scan mode, Settable over-limit Alarm |

||||

|

Displaying Content

|

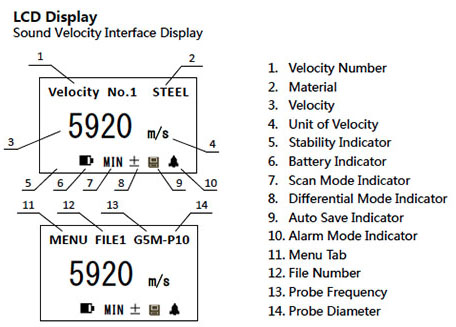

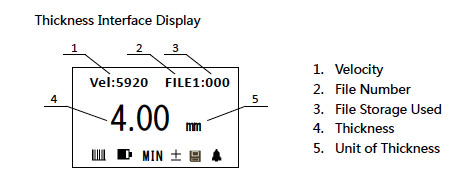

Thickness/Sound Velocity/Coupling/Batter/Alarming indicator/Differential indicator/scanning indicator/Storage, etc. |

||||

|

Storage

|

500 Groups, including thickness value, sound velocity, etc. |

||||

|

Communication

|

Mini-USB interface, virtual serial port protocol

|

||||

|

PC Software

|

Standard upgradable software, support online measurement |

||||

|

Printer

|

Optional Mini-printer

|

||||

|

Power Supply

|

3*AAA Batteries

|

||||

|

Working Hours

|

100 Hours (with backlight), Support timeout/ low battery power off |

||||

|

Working Condition

|

Usage:-10-50℃,Store:-30-60℃

|

||||

|

Packing Weight

|

2KG

|

||||

|

Dimension

|

36x25x14CM(LxWxH)

|

||||

|

Items

|

Qty.

|

|

Main Unit

|

1 Pcs

|

|

G5M-P10 Standard Probe (5MHz Dia.10mm)

|

1 Pcs

|

|

Coupling jel

|

1 Pcs

|

|

Communication Cable

|

1 Pcs

|

|

AA Battery

|

3 Pcs

|

|

ABS Shock-proof Instrument Case

|

1 Pcs

|

|

Manual Book, Quality Certificate, Guarantee Card, Packing List |

One Each

|

Optional Probes

|

Probe Type |

G5M-P10 |

G5M-P08 |

G2M-P12 |

G7M-P06 |

H3M-P12 |

|

Testing Range (in Steel) |

0.8-300mm |

0.8-300mm |

2.0-400mm |

0.75-40mm |

3.0-100mm |

|

Probe Diameter |

10mm |

8mm |

12mm |

6mm |

12mm |

|

Frequency |

5MHz |

5MHz |

2MHz |

7.5MHz |

3MHz |

|

Contact Temperature |

-10-60℃ |

-10-60℃ |

-10-60℃ |

-10-60℃ |

-10-310℃ |

|

Min. Testing Diameter |

Φ25x3 mm |

Φ20x1.2 mm |

Φ30x4 mm |

Φ15x1.2mm |

Φ25x3 mm |