Contact Us

Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

|

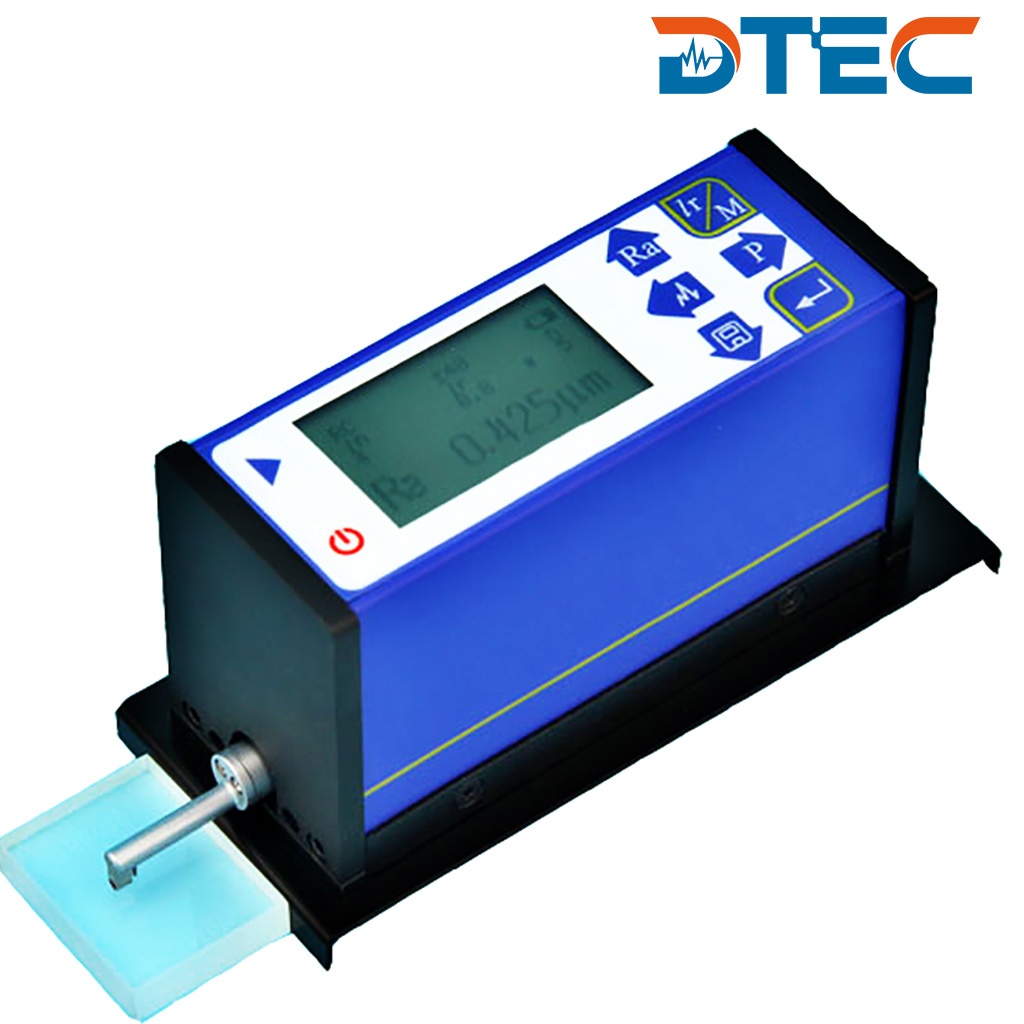

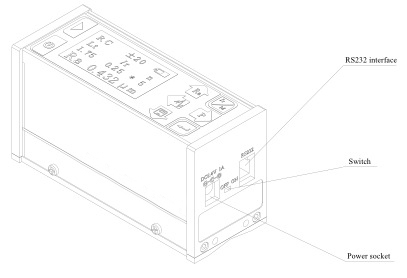

Product : Surface Roughness Tester

Model : DRT200

Country of Origin : CHINA

Brand : DTEC

Quality Certified : ISO,DIN,ANSI,JIS.

Delivery Time : 3 days

Packing Weight : 3KG

Dimension : 38×25×10cm(LxWxH)

Package Type : Maker's Standard Export Wooden Case

Courier : DHL/TNT/FedEx/UPS/EMS/Shipping Agent

Payment Term : TT100%/Private Bank Account/L/C/Paypal/Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

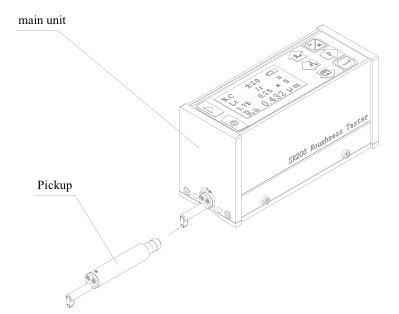

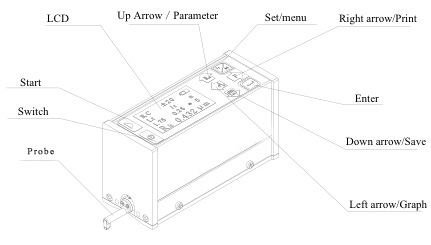

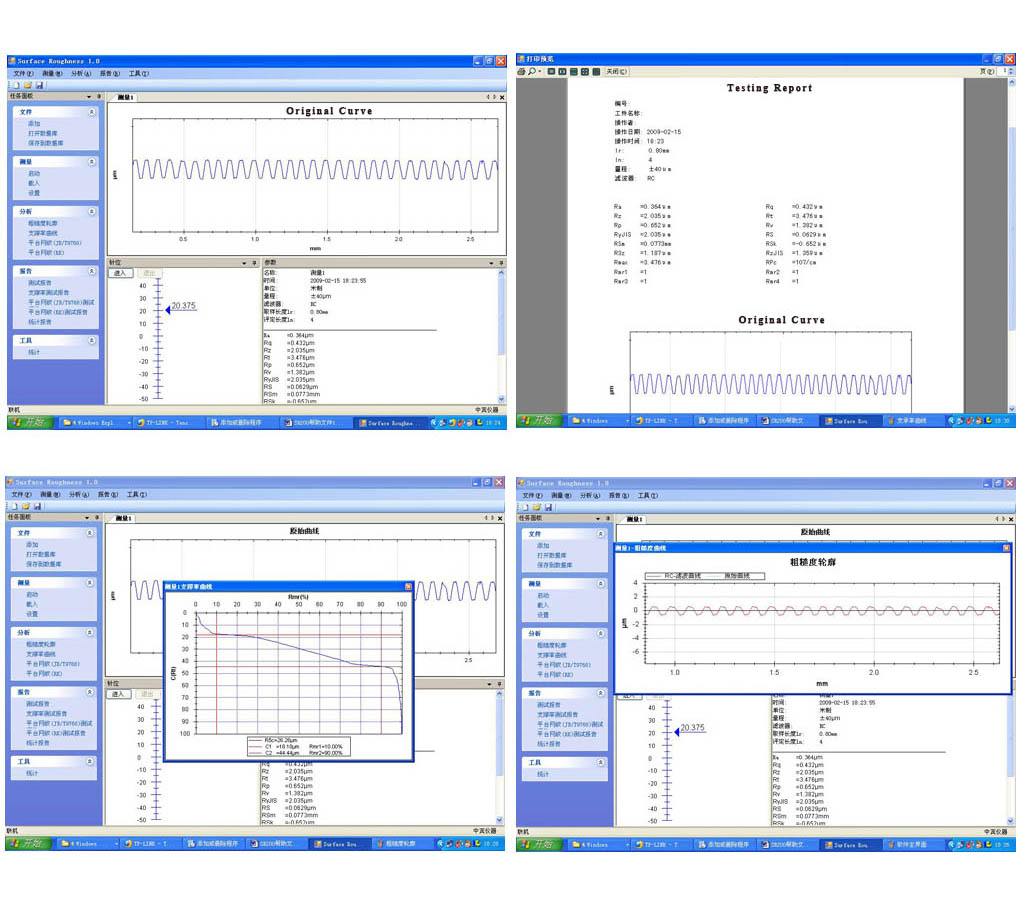

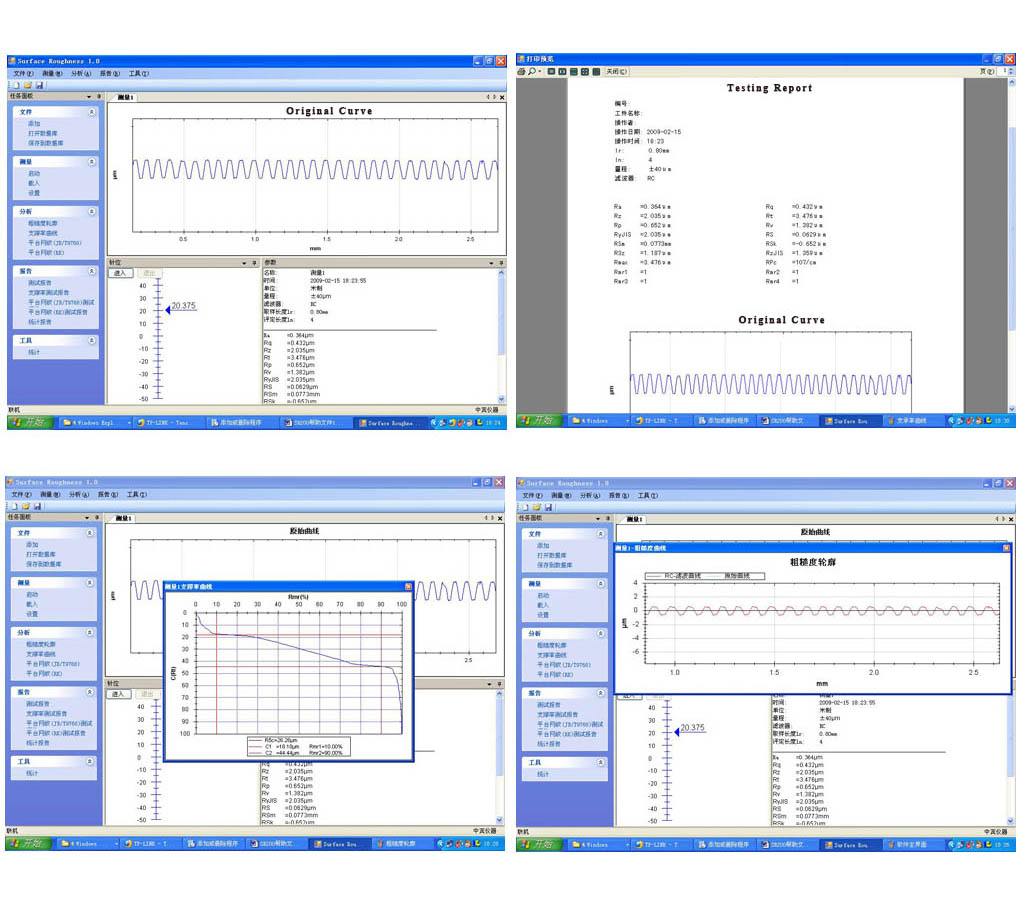

DRT200 Surface Roughness Tester is a kind of portable measuring equipment that is suitable for the need of various production environment and unfixed measurement, with easy and convenient in operation, comprehensive in function, fast in testing, stable in accuracy and easy to carry; it is capable of evaluating surface textures with a variety of parameters according to various latest national standards and international standards, strictly conforming to international standards; with RS232 data port, the machine can connect to PC and optional mini-printer.

Measuring principle

When measuring roughness on specimen surface, the probe is placed on the surface of the specimen, and then tracing the surface at constant rate. The probe acquires the surface roughness by the sharp stylus inside. The roughness on surface causes displacement of stylus which results in change of inductive value in induction coils, thus generates analogue signal which is in proportion to the tested surface roughness at the output end of phase-sensitive rectifier. This signal enters data collection system after amplification and level conversion. After that, those collected data are processed with digital filtering and parameter calculation by DSP chip and the measuring result can be read on LCD, or printed out through printer or communicated through PC.

Measuring principle

When measuring roughness on specimen surface, the probe is placed on the surface of the specimen, and then tracing the surface at constant rate. The probe acquires the surface roughness by the sharp stylus inside. The roughness on surface causes displacement of stylus which results in change of inductive value in induction coils, thus generates analogue signal which is in proportion to the tested surface roughness at the output end of phase-sensitive rectifier. This signal enters data collection system after amplification and level conversion. After that, those collected data are processed with digital filtering and parameter calculation by DSP chip and the measuring result can be read on LCD, or printed out through printer or communicated through PC.

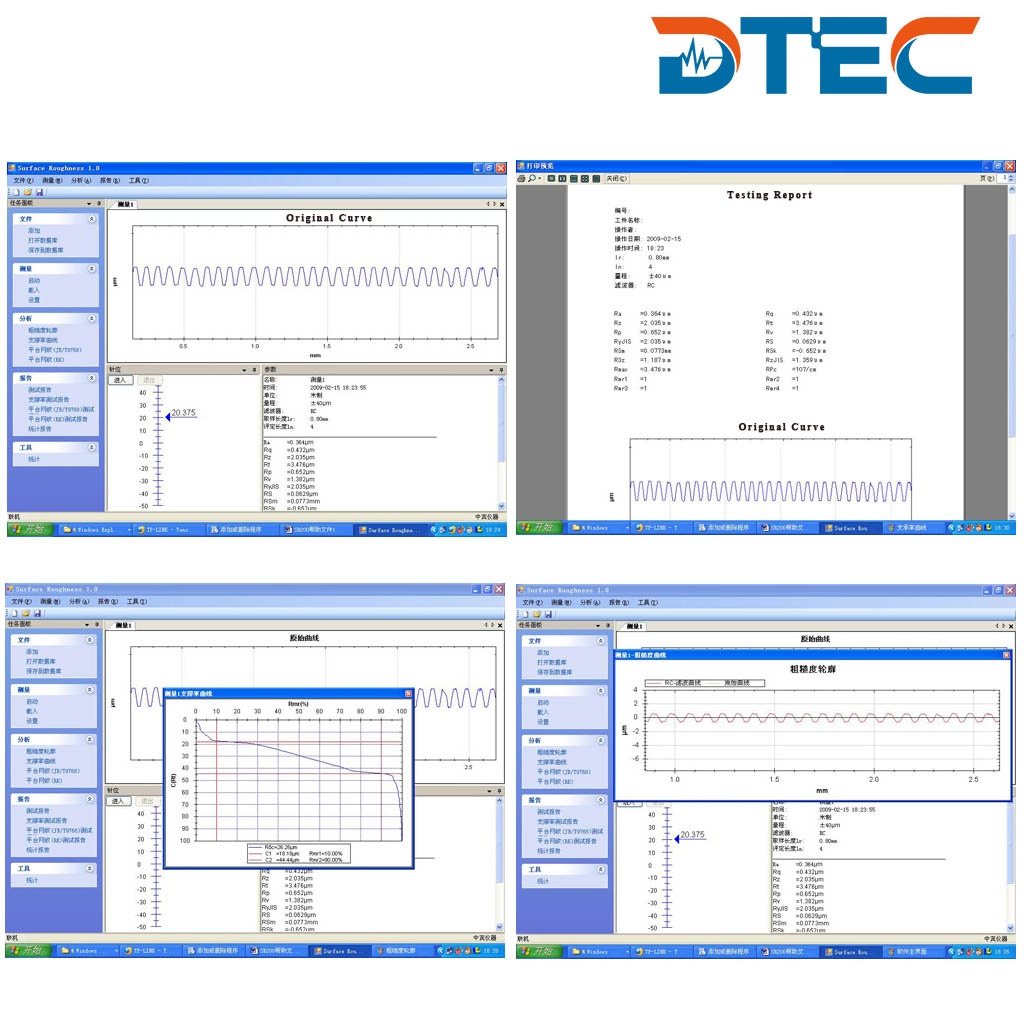

►15 parameters: Ra、Rq、Rz、Rt、Rp、Rv、RS、RSm、Rz(JIS)、Ry(JIS) 、RSk、R3z、Rmax、RPc、Rmr;

►4 filtering modes: RC, PC-RC, GAUSS and D-P;

►4 Compatible standards:ISO, DIN, ANSI and JIS;

►15 times measurements results storage;

►High accuracy inductance probe;

►128×64 dot matrix LCD Screen, displays all parameters and graphs;

►DSP chip is used to control and process data with high speed and low power consumption;

►Built-in lithium ion chargeable battery and control circuit have high capacity, without memory effect. Consecutive work time is longer than 20 hours;

►Design of mechanical and electrical integration, adopts to achieve small bulk, light weight and easy usage;

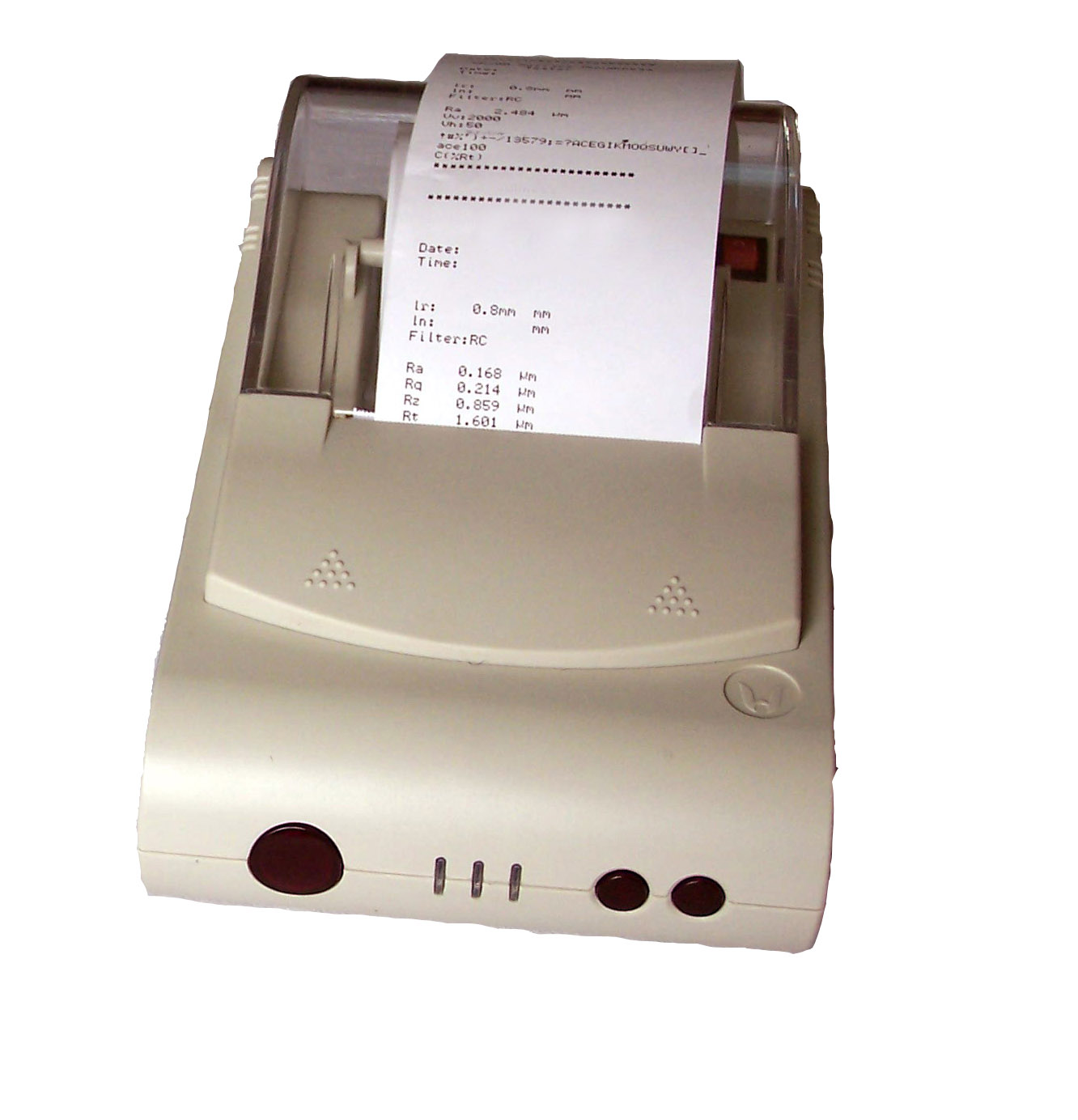

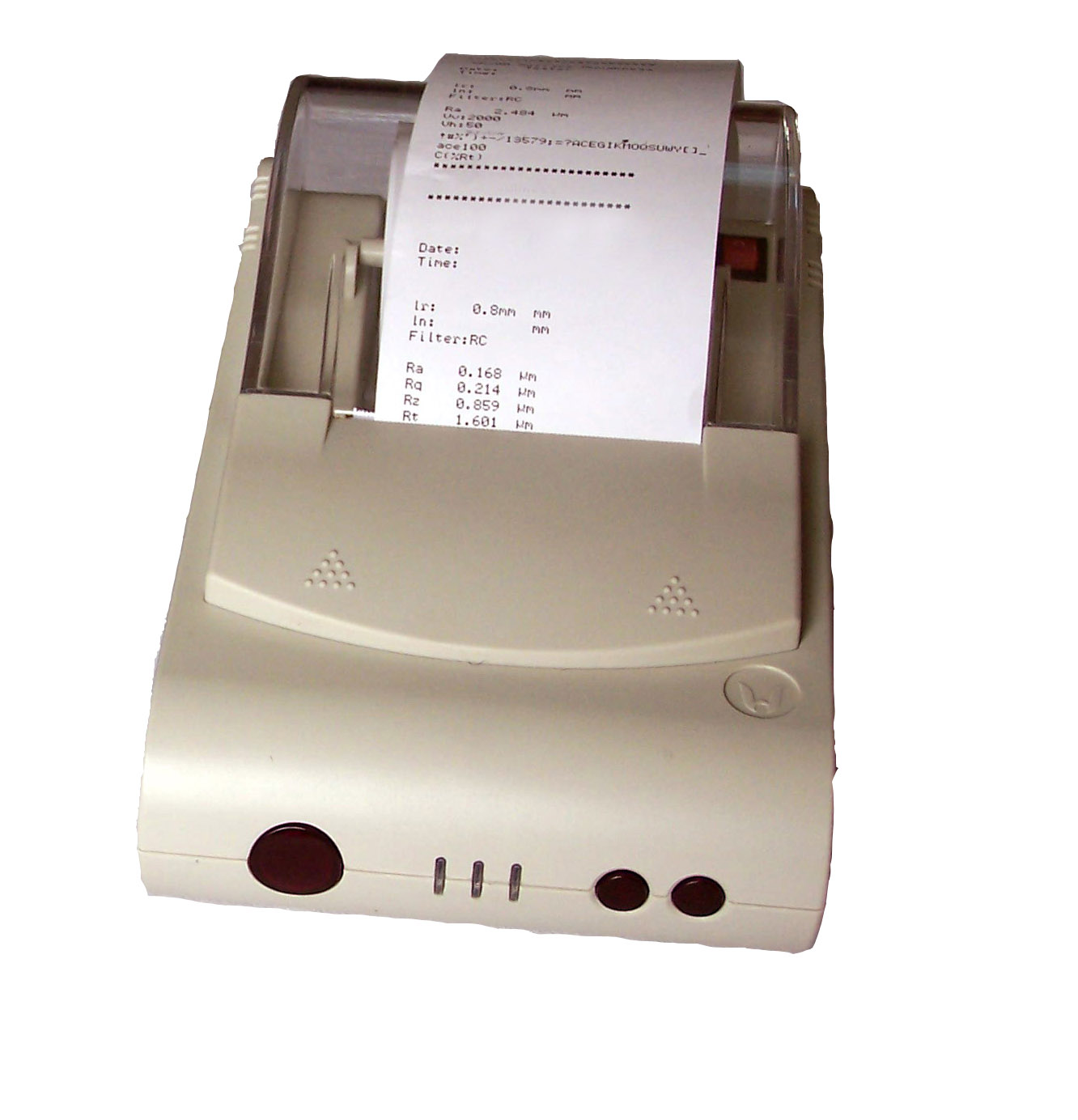

►Enable to connect to printer, all parameters and graphs can be printed out;

►Built-in standard RS232 interface, enables communication with PC;

►Automatic switch off, memory and various prompt instructions;

►Optional mini-printer, analysis software, special probes and measurement platform.

|

Measuring range |

Z Axis(Vertical)

|

Ra:0.025μm~12.5μm;160μm |

|

|

X Axis(Horizontal)

|

17.5mm

|

||

|

Resolution

|

Z Axis(Vertical)

|

0.01μm/±20μm

|

|

|

0.02μm/±40μm

|

|||

|

0.04μm/±80μm

|

|||

|

Measurement item |

Parameters

|

Ra、Rq、Rz、Rt、Rp、Rv、RS、RSm、Rz(JIS)、Ry(JIS) 、RSk、R3z、Rmax、Rpc、Rmr;

|

|

|

Standard

|

ISO,ANSI,DIN,JIS

|

||

|

Graphic

|

Roughness profile,Material ratio curve,Direct profile |

||

|

Filter

|

RC,PC-RC,Gauss,D-P

|

||

|

Sampling length (lr) |

0.25,0.8,2.5mm

|

||

|

Assessment length ln) |

Ln= lr×n n=1~5

|

||

|

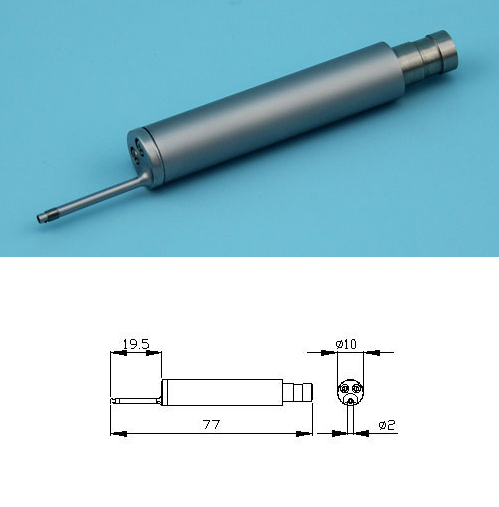

Probe

|

principle

|

Differential inductance |

|

|

Stylus

|

Natural Diamond, 90B cone angle, 5μm tip radius |

||

|

Force

|

<4mN

|

||

|

Skid

|

Ruby,Longitudinal radius 40mm |

||

|

Traversing speed |

lr=0.25, Vt=0.135mm/s

|

||

|

lr=0.8, Vt=0. 5mm/s

|

|||

|

lr=2. 5, Vt=1mm/s

|

|||

|

Return Vt=1mm/s

|

|||

|

Accuracy

|

Less than or equal to ±10% |

||

|

Repeatability

|

Less than or equal to 6% |

||

|

Power supply |

Built-in Lithium ion battery,AC adapter 8.4V,800mA |

||

|

Dimension

|

38×25×10cm(LxWxH)

|

||

|

Packing Weight |

3KG

|

||

Standard Packing Accessories:

Optional Accessories:

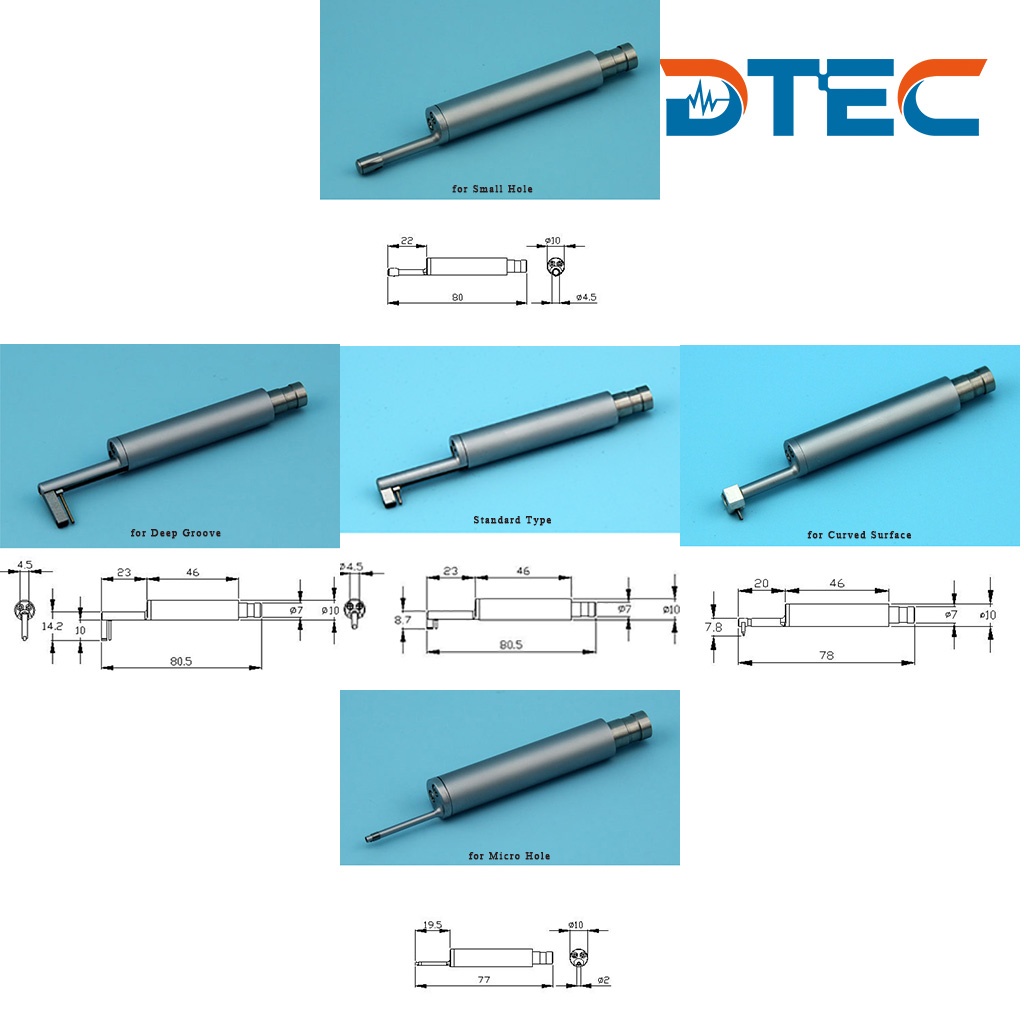

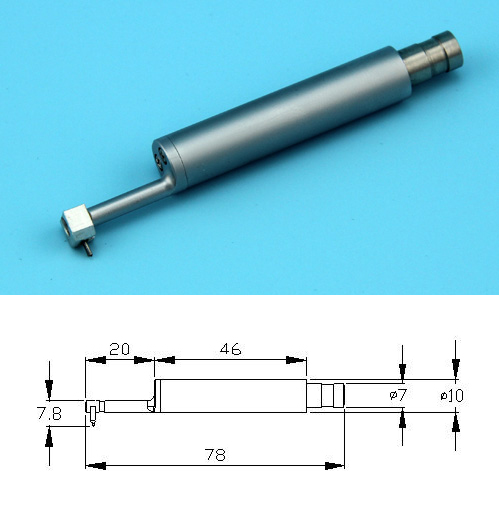

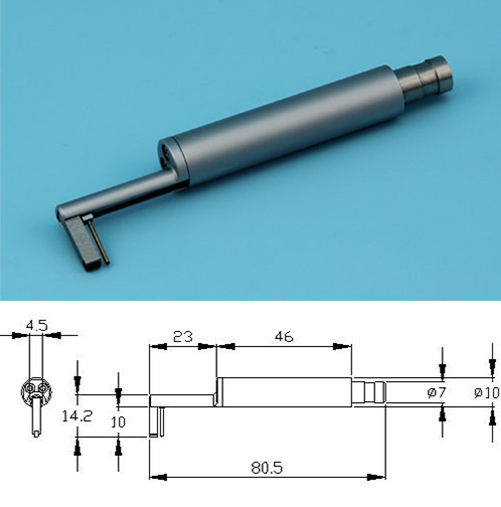

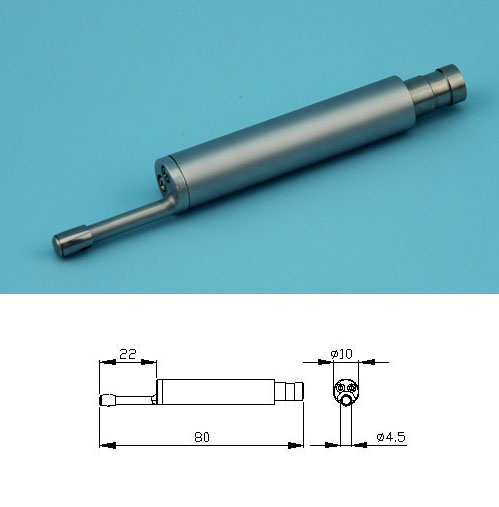

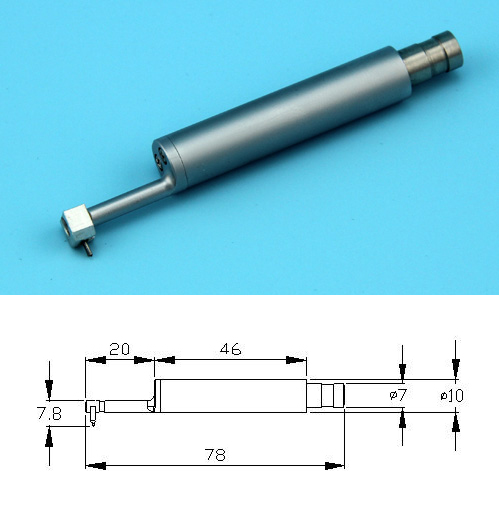

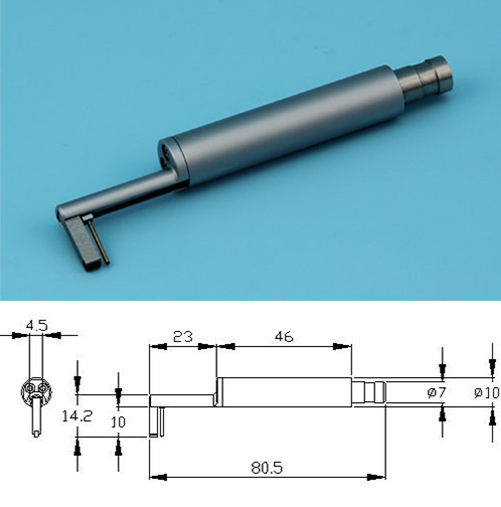

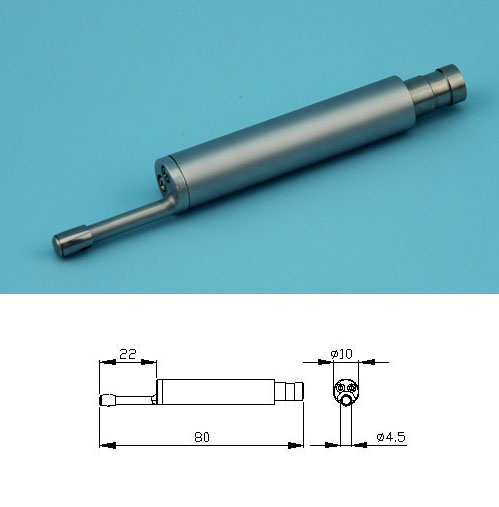

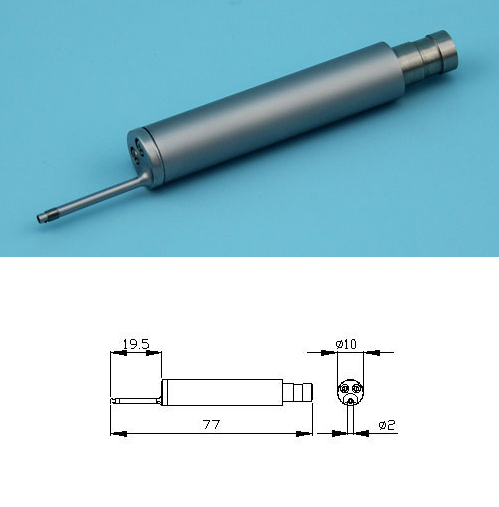

►Special Probes

Probe for Curved Surface

Probe for Deep Groove

Probe for Small Hole

Probe for Micro Hole

►Processing Software

►Mini Printer

►Fine Adjustment Platform & Stand

|

NO.

|

Items

|

Qty.

|

|

1

|

Main Unit

|

1

|

|

2

|

Standard Probe |

1

|

|

3

|

Screwdriver

|

1

|

|

4

|

Calibration Specimen |

1

|

|

5

|

Specimen Plate |

1

|

|

6

|

Power Adapter |

1

|

|

7

|

User’s Manual |

1

|

|

8

|

Produce Certificate |

1

|

|

9

|

Guarantee Card |

1

|

|

10

|

Case

|

1

|

Optional Accessories:

►Special Probes

Probe for Curved Surface

Probe for Deep Groove

Probe for Small Hole

Probe for Micro Hole

►Processing Software

►Mini Printer

►Fine Adjustment Platform & Stand